Mon Dec 24 '18 Announcement

over 5 years ago

– Mon, Dec 24, 2018 at 12:35:55 AM

Testing lab approved

As mentioned in the last update, we had to wait for our testing laboratory to be officially sanctioned so that we could rely on the test results for international certification. This required an inspector to fly from the UK to the US, which was scheduled for late November. Thankfully, that all went according to plan which meant we could proceed soon after with the certification application.

International certification application submitted

We have very recently officially applied for international certification. This is big step forward and one that we’ve been working towards all year!

As explained in previous updates, international certification is a two-stage process. The first stage relates to the product itself (product performance, product safety, etc.) and the second relates to manufacturing (quality control, factory audit, etc.). The application we’ve made recently is for the first, product-related certification.

The Christmas and New Year holiday period will get in the way of the first stage proceeding immediately but we should hopefully make solid progress with it in January. The second stage will begin after we receive first-stage approval. My hope is that both stages can be complete by the end of February but that will rely on everything progressing smoothly from here.

Next update

I’ll post another update at the end of February. Hopefully by then we’ll have received international certification and be ready for manufacturing!

Seasons greetings

Thank you so much for your support and patience this year. The testing and certification process has obviously taken longer than I’d expected but it’s great to finally be getting close!

Wishing you and your family a relaxing, fun and love-filled Christmas and holiday period. I look forward to sending you more SCORKL progress in the new year.

Sincerely,

David

Wed Nov 7 '18 Announcement

over 5 years ago

– Wed, Nov 07, 2018 at 07:15:11 PM

Waiting for testing lab to be sanctioned

In the last update I mentioned that now that we had successfully passed official testing we would look to begin the application process to receive international certification. I had hoped that we’d be progressing through that process by now but it has been delayed by a month or so. This is because our testing laboratory needs to go through an official sanctioning process itself before our testing results can be relied upon. The sanctioning processes will involve official inspectors flying from the UK to our lab in the USA which, as you can imagine, takes time to organise. My hope is that that will be complete by the end of November, after which we can formally submit our testing results and application for approval.

Timing update

As mentioned in previous updates the certification application process takes a month or two to approve, as will the assembly and delivery of orders. I had held out hope that we might still have been able to get orders out before the end of the year but that will no longer be possible, I’m afraid. Fingers crossed that we can be approaching the first stage of international certification approval before the new year though.

Waterproof carry cases samples received

We’ve recently received the first samples of the waterproof carry cases. The waterproof cases come with laser-cut foam which fit both the SCORKL and SCORKL PRO* sizes and which offer both land or air travel storing configurations.

You can take the SCORKL as either checked or hand luggage when flying on a commercial aircraft but airport security organisations such as the Transportation Security Administration in the USA require air cylinders to be visibly empty. This means that you must detach your regulator from the cylinder so that they can easily observe that the cylinder does not contain any pressurised air. In the photos below you can see the SCORKL and SCORKL PRO stored pressurised for land travel, or non pressurised for air travel.

__

* - So far only Kickstarter backers, but not Indiegogo backers, have been given the opportunity to upgrade to the SCORKL PRO (which holds ~20% more air than the SCORKL) or purchase the small waterproof carry case. That occurred when I sent the Backerkit ‘backer survey’ to Kickstarter backers soon after the Kickstarter campaign concluded, offering the opportunity to upgrade packages and add add-ons. I’ll wait until just prior to shipping all the Kickstarter and Indiegogo orders to offer the same opportunity to Indiegogo backers (and again to Kickstarter backers that missed out the first time).

Next update

The next update will be posted in late December. I hope to be able to report good progress with the certification approval process then. Thanks as always for your ongoing patience and support.

David

Tue Sep 25 '18 Announcement

over 5 years ago

– Tue, Sep 25, 2018 at 03:26:19 AM

Hi everyone. Time for another update. Some great news to report below:

Valve seal issue fixed

In the last update I showed that the valve seal, a small plastic part inside the cylinder valve, was being affected slightly after storage at high and low temperatures. Even though the shape was only changing slightly it unfortunately meant that performance was being negatively impacted.

To fix this problem we needed to find a new plastic to make the seal out of, one that wouldn’t be affected by the high and low temperatures and high pressures. This is easier said than done since the plastic also needs to be suitable for high precision moulding. There can be no imperfections in the roundness of the valve seal head otherwise the valve leaks, if only very slightly.

After making new moulds of the valve seal with five different new plastics, we re-tested each at high and low temperature storage, and pressure.

Our temperature storage machine

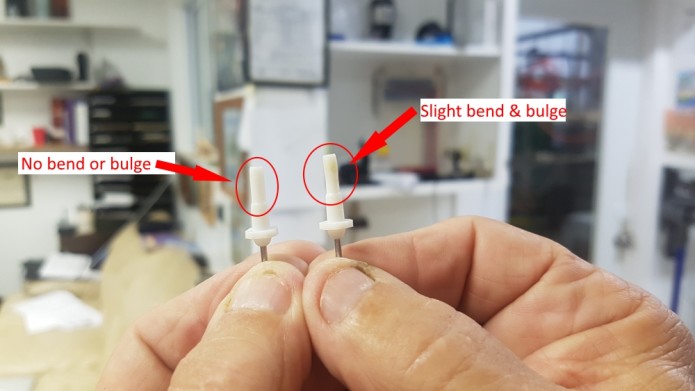

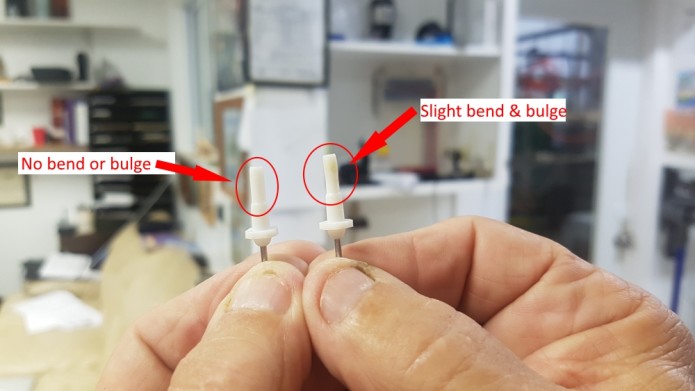

The testing highlighted one type of plastic to be perfectly suited to what we needed. All valve seals will be made from this new type of plastic from now on. In the photo below, you can see the old and new valve seals. The old version is on the left, and the new one is on the right.

Old Vs New Valve Seal

Old Vs New Valve Seal

This process of ordering new seals to be moulded from five different plastics, and testing them, took about five weeks.

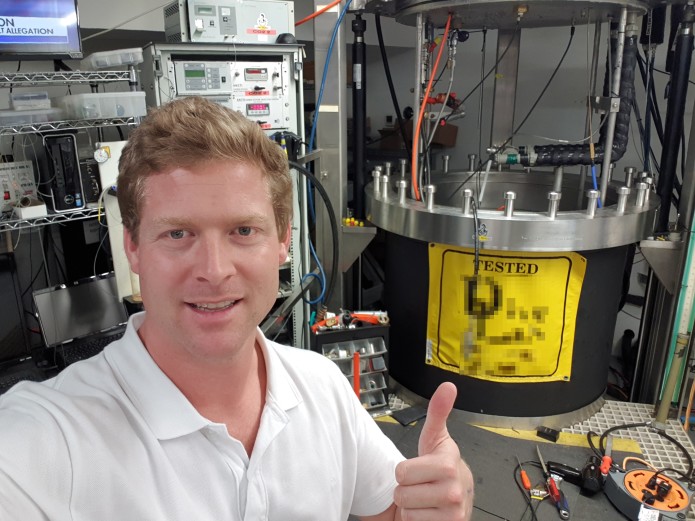

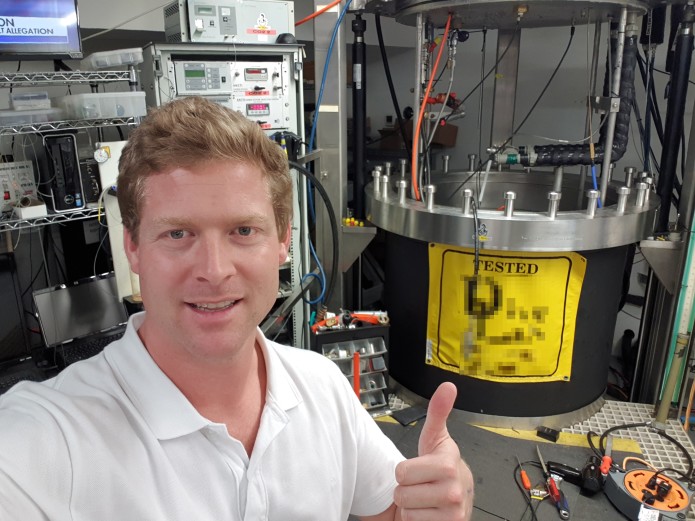

Official testing success!

After settling on the new valve seal I endeavoured to schedule re-testing at the dive laboratory as soon as I could and we were fortunate enough to be able to get back in there at relatively short notice, for my third visit in four months.

I am very pleased to report that it was a great success! The valve seal plastic change held up as expected and the regulator performed within all the safety and performance standards required by international standards. This was quite an achievement since those performance and safety standards are the same standards applied to two-stage scuba regulators that are capable of diving to 50m (160 ft). (Please note however that the SCORKL won’t be certified to those same depths since it is only intended for shallow water use.)

As you all know, it has been a challenge to get to this stage where we now have successful ‘official’ test results that can be relied upon for international certification. Although lengthy, the process has been essential. Not only has it yielded two significant product improvements but you can all now be totally confident that your SCORKL meets the highest international safety and performance standards when you receive it.

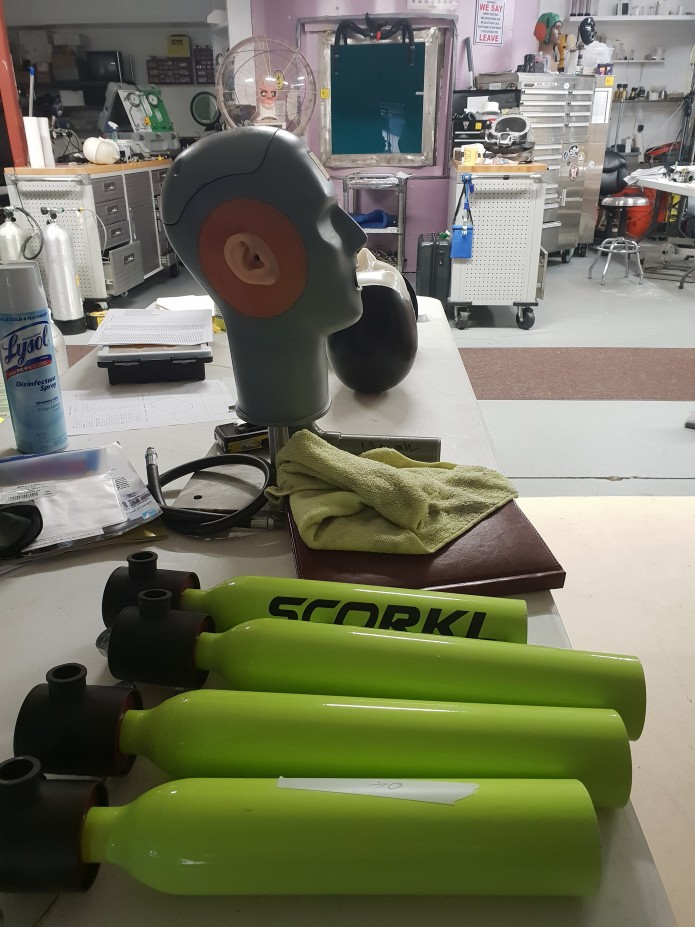

The four units that underwent 'official' testing

The four units that underwent 'official' testing

Exhalation valve test @ 300 L/min

Exhalation valve test @ 300 L/min

Success!

Success!

Certification application

Now that we have official testing results, the next step is to apply for international certification. Part A of the application process is to collate and submit a file that provides comprehensive detail about the product itself. This will include; the ‘official’ performance and safety testing results (as mentioned above), the cylinder and cylinder valve testing reports (mentioned in previous updates), engineering drawings, safety manual, etc.. Part B of the application process will be to undergo a manufacturing quality control audit at our factory.

Both Part A and Part B are relatively straightforward in theory but will no doubt prove a little less straightforward in practise. We will once again be in a position where we will be waiting on how quickly third parties (the certifying agency, manufacturing quality control auditor) move so timing may be unpredictable. I hope that the certification process will take less than two months but we will have to wait and see. I'll be doing my best as always to move things along as quickly as I can.

Next update

The next update will be posted in early-mid November. Fingers crossed that our certification approval has progressed substantially by then!

Thanks as always for your ongoing patience and support.

David

Thu Aug 2 '18 Announcement

over 5 years ago

– Thu, Aug 02, 2018 at 03:39:58 AM

Thanks as always for your patience. Update time.

New diaphragm working well

In the last update I showed a photo of the new better-fitting diaphragm that we had moulded over the month prior. After testing it extensively at the specialised dive laboratory in July, we are now confident that it works perfectly which was a great result and a solid step forward.

--

--

Valve seal compound needs to be changed to improve durability

I had hoped that the most recent testing period would be the final one that we needed to do but it uncovered another issue with the valve seal that needs fixing.

One section of the international certification tests that we are testing the SCORKL to requires that the product be subjected to 3 hours of storage at 70 degrees Celsius (158 degree Fahrenheit) and 3 hours of storage at -30 degrees Celsius (-22 degrees Fahrenheit). This storage occurs while the product is pressurised to 50% of the working pressure (200 bar or 3,000psi). These “Resistance to temperature” tests ensure that the product will still perform well even if it suffers accidental storage in hot or cold temperatures. -30 degrees Celsius (-22 degrees Fahrenheit) is obviously super cold, so specialised equipment is required. You can see the machine that keeps the SCORKLs stored at -30 degrees Celsius here:

--

__

What we discovered was that even though some of the units performed fine after the temperature storage, others didn’t. We found out that the valve seal, a small plastic part inside the cylinder valve, was sometimes getting affected by the heat (and pressure). Under pressure and heat, the plastic would sometimes change shape slightly, negatively impacting performance. In the photo below you can see how the shape of the valve seal on the right is not as perfectly straight as the valve seal on the left. The valve seal on the right has been subjected to temperature storage whereas the one on the left has not.

--

--

Even though the change in shape is only very slight, it has a negative effect on performance since the regulator operates at such high pressures. To be 100% confident that no units can be affected in this way in the future, we’ll need to change/improve the valve seal. This will most likely occur by using a higher quality plastic with a higher resistance to temperature.

Overall, it should be a relatively straightforward change but as with all these things, it will take time. We’ll need to decide on the new compound, mould new samples and then test them. As with the new diaphragm it may take a few iterations to land on a suitable change. I expect this process to take between three to six weeks.

Final official testing. Certification application. Christmas time frame now tighter

Only after we have made the above change will we be able to undergo the official tests for international certification that is required before we can ship. There is still enough time for certification, assembly and shipping to occur before Christmas but the time frame is now tighter. Fingers crossed everything runs smoothly from here on in and we can still meet the pre-Christmas shipping date.

Logistics

Thanks again to those people who reached out with advice or to help with the logistics side of things. I’m still focusing on certification first but will get back in touch as soon as appropriate.

Next update

I’ll post another update at the end of September. Hopefully by then we’ll have fixed that valve seal issue and have completed the official testing for certification.

Thank you as always for your support and patience.

Sincerely,

David

Tue Jun 26 '18 Announcement

almost 6 years ago

– Tue, Jun 26, 2018 at 01:56:35 PM

Update time. Thanks everyone as always for your patience.

New better-fitting diaphragm

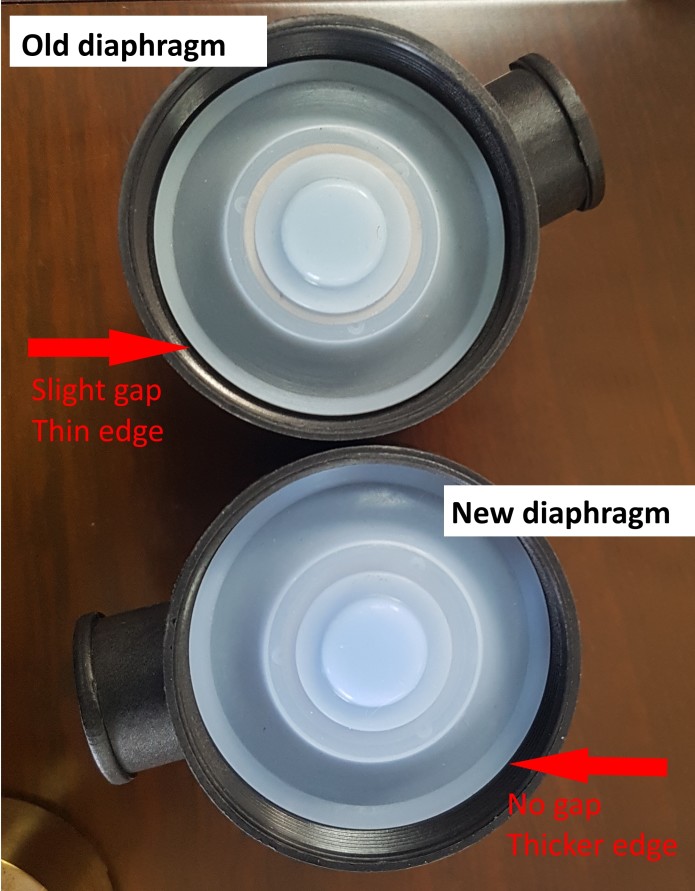

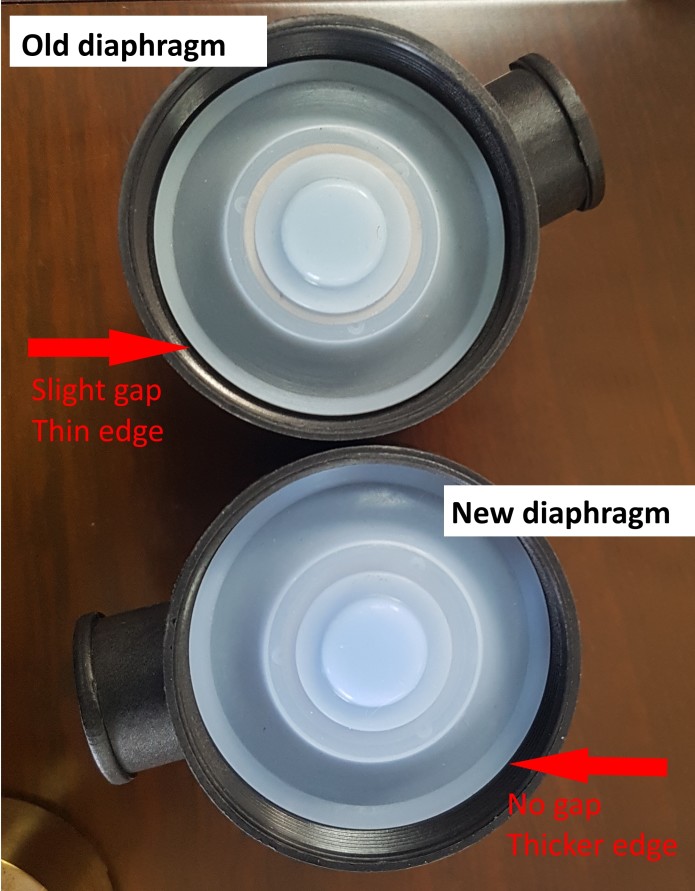

In the last update I mentioned that after initial testing we needed to improve the fit of the diaphragm inside the breathing regulator since that was preventing us from being able to perform the “official” performance tests for international certification. It took time but we now have a much better fitting diaphragm.

In the photo below, the diaphragm is the blue/grey rubber disk and you can see both versions. The diaphragm at the top is the old one and the one at the bottom is the new one. You can see that there is a small gap between the circumference (outer edge) of the old diaphragm and the wall of the regulator body, whereas the circumference of the new diaphragm fits flush. You can also see that the outer edge of the new diaphragm is slightly thicker than the old one.

Both of these changes mean that the new diaphragm fits much better into regulator body. This will improve the regulator’s performance and safety under all conditions. The changes might not look like much but it took a few iterations to get the mould just right and it is an important improvement resulting from the testing process.

Timing Update

It took three iterations to get the diaphragm mould perfect, each process lasting about two weeks (6 weeks total). The next step is to hopefully perform the “official” certification tests at the specialised dive laboratory in early July and if the testing goes well, to apply for international certification soon after.

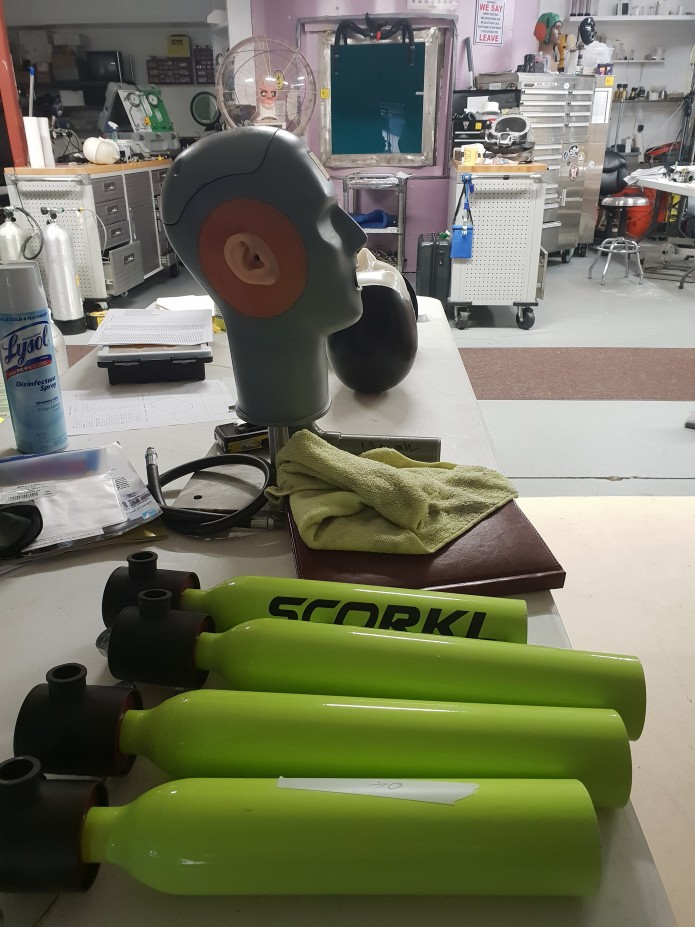

Even though most of the regulator parts (see photo below) and pumps have already been manufactured, the a) manufacturing of the cylinders b) assembly of parts and kitting of the packages, and c) shipping of the orders, will take about one month each. If we can receive international certification by the end of August that will hopefully mean I can get orders into your hands before Christmas.

As you are already well aware, that will be twelve months behind schedule. Being an underwater breathing device with high pressure components, the SCORKL is required to meet the highest international performance, safety and manufacturing standards and meeting those standards has unfortunately taken much longer than anticipated. It is obviously an essential process to go through though so I am continually grateful for your generous patience and support.

Logistics

Thank you to everyone who replied with suggestions or offers to help with logistic solutions after my request in the last update. I haven’t replied to you yet I’m sorry but that was because my priority was to get that diaphragm fit right first. I’ll be in contact with you each before the next update to discuss, as I look to formalise the logistics plans.

Manual

I’ve begun preparing manuals for the SCORKL and Pump and we had a photoshoot for it just the other day. Here are a couple of the behind the scene stills:

Communications

As mentioned in previous updates, there have now been over 3,000 orders across Kickstarter and Indiegogo which means I receive many messages across those two platforms, plus Facebook and Instagram, every day. The most efficient way by far for me to communicate with everyone is via these updates, so please excuse me if you do not receive a personal reply to a direct message immediately. I do eventually get around to answering everyone but mainly try to do that around the same time that I post an update (about once every 6 weeks). Doing things this way means I can focus my efforts on getting the orders shipped ASAP, rather than spending too much time on emails. Sorry if this makes it appear as though I am neglecting your inquiries or public comments but hopefully you can understand that it is well-intentioned.

Next Update

I’ll post another update in early-mid August and hopefully by then I’ll be able to report back with successful “official” testing results and the progress of the international certification application.

Closing Note

Thank you, thank you as always for your patience. One year ago today we were right in the middle of the four week Kickstarter campaign. A huge amount has happened since then. We’re getting very close and I’m very hopeful that you’ll be pleased with the result when we eventually get over the final hurdles.

Sincerely,

David

Old Vs New Valve Seal

Old Vs New Valve Seal The four units that underwent 'official' testing

The four units that underwent 'official' testing Exhalation valve test @ 300 L/min

Exhalation valve test @ 300 L/min Success!

Success!